CNC milled plugs, production moulds and direct moulds

A well manufactured, high quality plug is essential to making moulds for all end products, from small components to large sections.

Plugs

A well manufactured, high quality plug is essential to making moulds for all end products, from small components to large sections. An accurate plug, with a high quality finish, is the end result, ready for mould making. The plugs are milled by 5 axis CNC milling machine for machining of composite materials. CNC machine produces plugs with the surface tolerances of up to 0.17-0.2 mm and therefore it is possible to produce large high-quality plugs.

Composite Plus requires 3D models of the products. The models must be created using a program that supports a file format that can be imported into the formats such as PARASOLID, STEP or IGES etc. A plug that has been CNC milled, must be sanded and polished before it can be used to take a production mould. Composite Plus`s plugs are tailored to the customers’ needs. All plugs are manufactured on a foundation of rigid plywood or steel frame. The surfaces of the ready-milled plugs consist of special modelling paste.

Production moulds

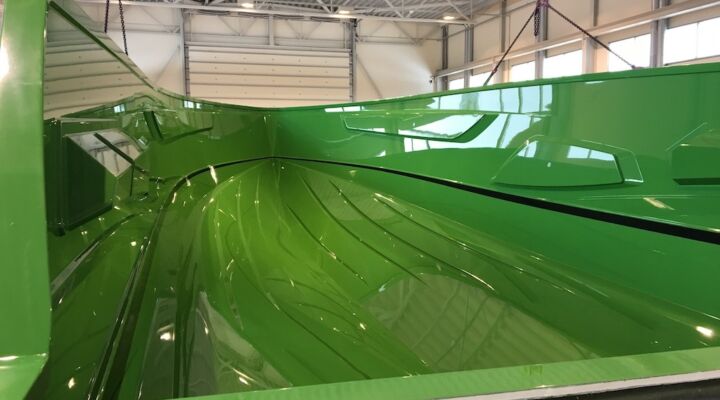

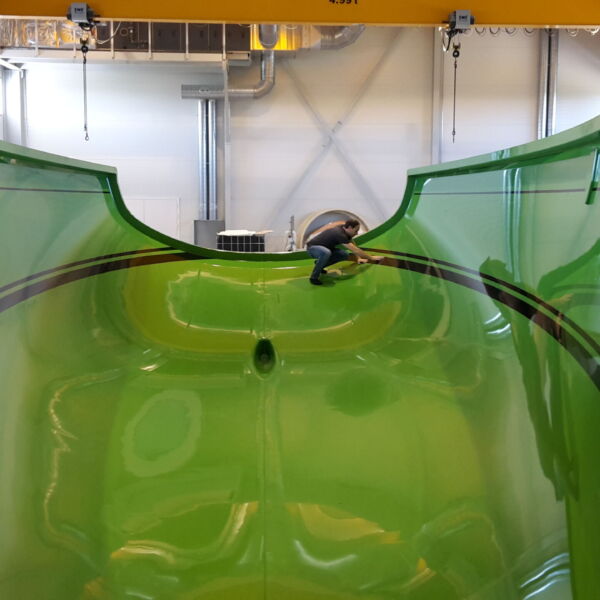

The manufacturing of high-quality fibreglass production moulds is a key service offered by Composite Plus. Designed to client specifications using the latest 3D-software systems, our moulds are developed and produced with the aid of our extensive experience to meet high quality and durability standards. Our precision quality gives you better results – high productivity, low surface-finishing costs and repeatability.

The moulds manufactured by Composite Plus are always done with the best materials and used the latest Tooling Systems. In GRP industry, only materials with the best product properties are used for producing the highest quality moulds. Extremely resistant to styrene and heat, high mechanical loading capacity, a permanently good degree of gloss as well as dimensional accuracy are the decisive criteria when it comes to selecting a reliable Tooling System. Large moulds traditionally take weeks or even months to build, prepare and commission.

The whole process is much faster thanks to the new generation of rapid tooling systems – RTS. High performance rapid tooling system based on tough, high temperature resistant vinyl ester gel-coat and resins that can cope with the high mechanical and physical demands during tool making and moulding. We are continuously testing and recommending available materials in the market to our customers in order to secure the optimal material choice for any product solution. This requires close cooperation with both our customers and our suppliers.

Composite Plus provides all 3D drawings of the mould reinforcements. Frame engineering is realized with the help of the up-to-date 3D software. For sufficient rigidity we reinforce the mould with metal frame. Manipulation and turning systems could be realized upon manufacturing procedures. Each frame is engineered according to the client`s specifications, in order to satisfy any production requirement.

We pursue the strategy of innovation, on behalf of our customers, as we believe trust and leadership in industry comes with the best ideas, consistency in quality and precision. Only by having this focus, may Composite Plus provide a solution that matches the expectations of our customers.

Direct moulds

A well manufactured, high quality plug is essential to making moulds for all end products, from small components to large sections. An accurate plug, with a high quality finish, is the end result, ready for mould making. The plugs are milled by CNC milling machine for machining of composite materials. CNC machine produces plugs with the surface tolerances of up to 0.17-0.2 mm and therefore it is possible to produce large high-quality plugs.

Composite Plus requires 3D models of the products. The models must be created using a program that supports a file format that can be imported into the formats such as PARASOLID, STEP or IGES etc. A plug that has been CNC milled, must be sanded and polished before it can be used to take a production mould. Composite Plus`s plugs are tailored to the customers’ needs. All plugs are manufactured on a foundation of rigid plywood or steel frame. The surfaces of the ready-milled plugs consist of special modelling paste.

More questions regards to our products & services?

Then feel free send us a e-mail or give us a call and we’ll go from there!