Technologies

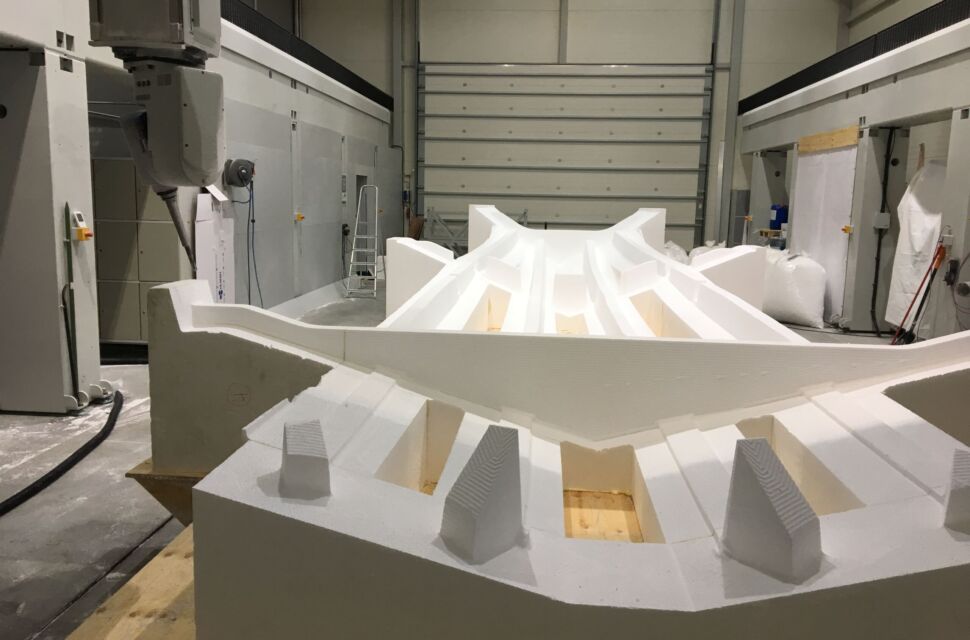

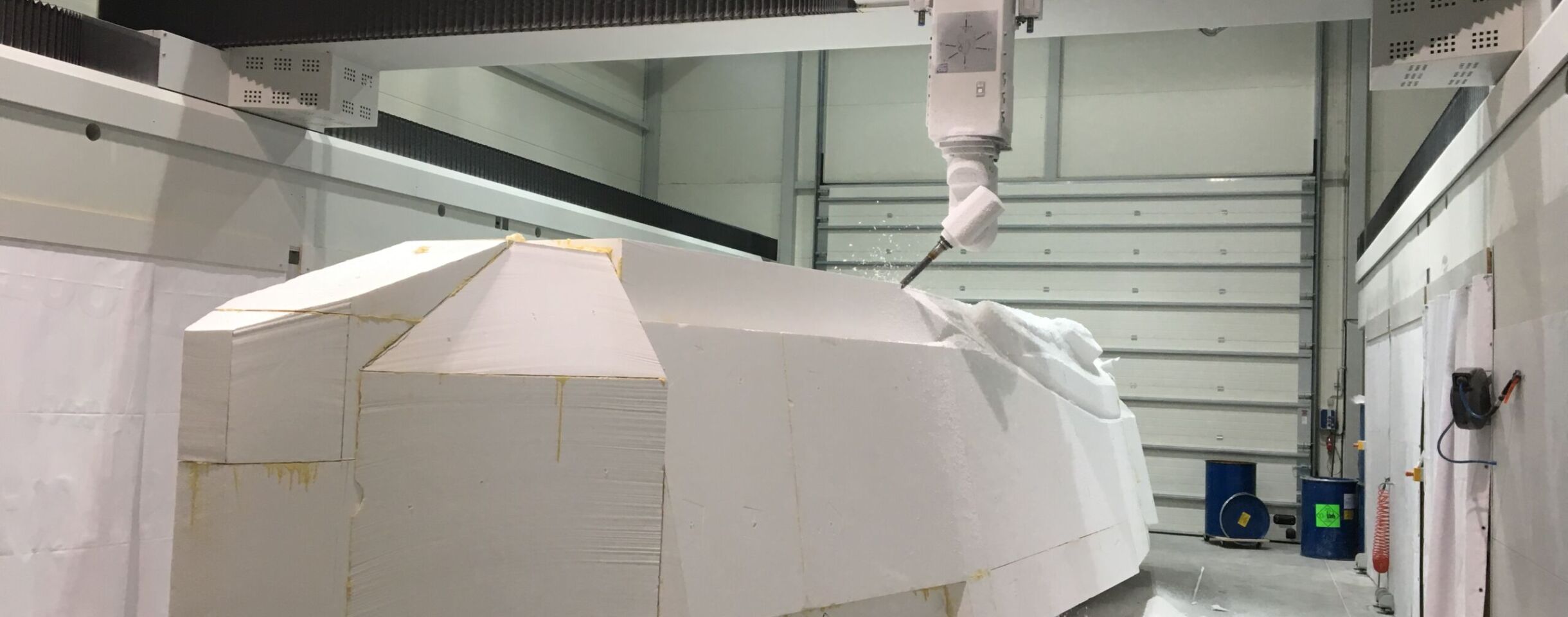

Composite Plus uses in his production a range of advanced composite manufacturing techniques and conventional quality lamination.

We are committed to provide innovative, well-engineered and state-of-the-art solutions to our customers.

The advanced technologies, which Composite Plus often uses, are closed moulding processes. These technologies offers many benefits when compared to conventional hand lay-up techniques in way of improved consolidation, lower void content, reduced resin content and far better repeatability.

As it is a closed mould process, it virtually eliminates potentially harmful volatile organic compound emissions and is also a very clean process. The range of technologies, which we use in our production.

Industries

- Marine

- Wind power

- Aqua culture

- Offshore-Seismic

- Construction & Architecture

- Other products